Integrated Quality System

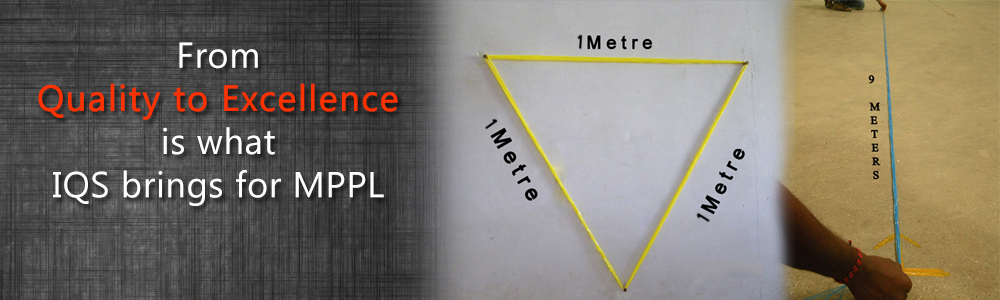

From Quality to Excellence is what IQS brings for MPPL.

At Muscat Polymers, we believe in stepping and attaining an extra mile. With a continuous process of quality improvement and commitment to comply with international quality norms, Muscat Polymers has established long term relationships with thousands of our valued clients winning their trust through innovative products, unmatched quality and dedicated customer care services. To ensure that the products we maintain adhere to international quality standards and offer superlative performance.

We supply top quality with enhanced durability woven sacks; we control the product quality in accordance with ISO9001 quality control system.

Right from the production of tape till making of final bag, each bag produced by us passes stringent quality control checks at every stage, which makes bags made by us like especially handmade for you.

Our tape plant can produce 1400 k.g. of tape per hour and is from world renowned Lohia Starlinger group. The Looms are also ultramodern and high speed which can produce almost defect free fabric. The same translates into final bags with very good quality.

Quality control tests at every stage of the manufacturing process

Tape Plant - At tape plant level, every lot of the produced tapes is checked for its denier & strength

Beta Gauge - We also have the Beta gauge machines which continuously checks the size and the denier of the tape.

Fabric Checking - Fabric produced by every loom is checked for right weaving, width, strength and finish.

In Process Checking - Checking of all the parameters required at the semi-finished & finished stage which mainly includes, cutting & stitching

In House Printing - Printing is checked for print quality, adherence of ink, and stitching is monitored with reference to the specifications

Tensile Test - Tensile and breaking strength of all the lots is checked on Tensile Tester

Various Necessary Tests - Load Test, Length & Width Test, Gusset Test, Valve Test, etc. are also carried out.

Complete Inspection - Full detailed inspection is carried out at each and every level to ensure the bags are made with the tolerance allowance.

Rig Test - Rig test are performed over the bags to ensure the load bearing capacity of each bag.

Bundle & Bales Checking - Final inspection is carried on the bundles and the packed bales to ensure that no loop holes are observed before the bales are been put on the container for shipment

After such extensive quality control operations at our in-house quality testing lab, there remains not an iota of doubt about the superlative quality of our finished products.

For any questions on the details about the quality procedure and implementation of quality control and standards, please contact our Quality team.

Contact: Mr. JC, Head, Quality Control Muscat Polymers Pvt. Ltd.

Email: info@muscatpolymers.com

An ISO certified ISO 22000:2018 certified company

An ISO certified ISO 22000:2018 certified company